Sanitary Pad Raw Material Composition and Properties

# Sanitary Pad Raw Material Composition and Properties

Sanitary pads are essential personal care products designed to provide comfort and hygiene during menstruation. Understanding the raw materials used in their production is crucial for ensuring quality and safety. This article delves into the composition and properties of the primary raw materials used in sanitary pads.

## 1. Absorbent Core

The absorbent core is the heart of a sanitary pad, responsible for absorbing menstrual fluid. It is typically made from a combination of:

– **Cellulose Fluff Pulp**: This is the primary absorbent material, derived from wood pulp. It is highly absorbent and provides bulk to the pad.

– **Superabsorbent Polymers (SAP)**: These are synthetic materials that can absorb and retain large amounts of liquid relative to their own mass. SAP enhances the absorbency of the pad, preventing leakage.

## 2. Top Sheet

The top sheet is the layer that comes into direct contact with the skin. It is designed to be soft, comfortable, and quick-drying. Common materials include:

– **Nonwoven Fabrics**: These are made from synthetic fibers like polypropylene or polyester. They are lightweight, breathable, and provide a smooth surface.

– **Perforated Films**: Some pads use perforated plastic films that allow liquid to pass through quickly while keeping the surface dry.

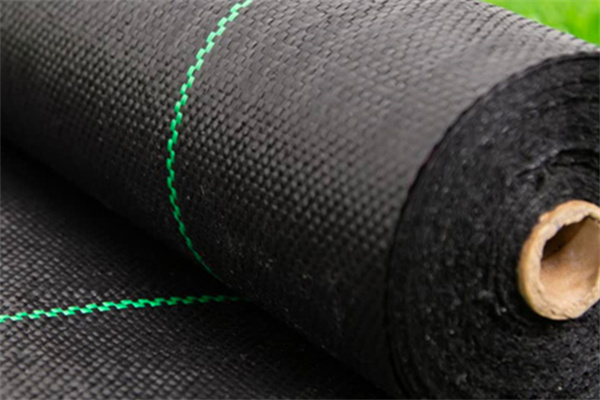

## 3. Back Sheet

The back sheet is the outermost layer of the pad, designed to prevent leakage and provide a barrier against moisture. Materials used include:

– **Polyethylene Films**: These are thin, flexible, and waterproof, making them ideal for preventing leaks.

– **Breathable Films**: Some high-end pads use breathable films that allow air to circulate, reducing the risk of irritation and discomfort.

## 4. Adhesives

Adhesives are used to secure the pad to the underwear. They must be strong enough to hold the pad in place but gentle enough to avoid skin irritation. Common types include:

– **Hot Melt Adhesives**: These are applied in a molten state and solidify upon cooling, providing a strong bond.

– **Pressure-Sensitive Adhesives**: These adhere to surfaces upon application of light pressure and are commonly used for their ease of use and reliability.

## 5. Release Paper

Release paper is used to protect the adhesive before the pad is used. It is typically made from:

– **Silicone-Coated Paper**: This type of paper is easy to peel off and does not leave residue on the adhesive.

## Properties of Sanitary Pad Raw Materials

The raw materials used in sanitary pads must possess specific properties to ensure effectiveness and comfort:

– **Absorbency**: High absorbency is crucial for preventing leaks and maintaining dryness.

– **Softness**: The materials should be soft to prevent irritation and provide comfort.

– **Breathability**: Good air circulation helps reduce the risk of skin irritation and discomfort.

– **Flexibility**: The pad should be flexible to conform to the body’s shape, ensuring a secure fit.

– **Hypoallergenic**: Materials should be non-irritating and safe for sensitive skin.

Understanding the composition and properties of sanitary pad raw materials is essential for manufacturers to produce high-quality products that meet the needs of consumers. By selecting the right materials, manufacturers can ensure that their sanitary pads are comfortable, effective, and safe for everyday use.

Keyword: Sanitary pads Raw Material